Product Design Work!

Thursday, 13 October 2011

AS Notes

After finding out that my client liked the High Tech design movement,I then wanted to base my design on a certain architect/designer from that design movement. To find this information , I emailed my client asking him as to what architect/designer he liked from the High Tech design movement. I also included a Power Point with several architects/designers from the High Tech design movement (as seen on the right hand side). By doing this, it allowed me to gain some very important information. This would assist my design as I knew what colours, shapes and angles to use when doing my initial ides. I also wanted to incorporate the shapes from certain buildings in to my design.It also indicated to me as to what my client wanted!

Wednesday, 5 October 2011

Thursday, 29 September 2011

Thursday, 8 September 2011

Manufacturing process - Plastics

Injection moulding

Granulated or powdered thermoplastic material is heated, melted and the forced under pressure into a mould. Once in the mould the material cools, forming a component that takes the shape of the mould cavity.

Rotational moulding

Rotational moulding is a process used mostly to create hollow items e.g. tennis balls etc. and uses plastics or polymers in which to do so. The plastic that is used is usually in the form of powder as it is easier to heat and saves space during transportation. The mould is heated so when the material is placed in the mould it is heated and therefore can flex into a variety of shapes. The mould is slowly rotated so the heated plastic sticks to the outside of the walls (centripetal force) of the mould to create the hollow item. The precise amount of material which is usually plastic has to be weighed very precisely so that some parts of the item are not thicker than other parts. The mould continues to rotate during the heating phase so that the end result is not deformed in any way. Once in the mould the material cools, forming a component that takes the shape of the mould cavity.

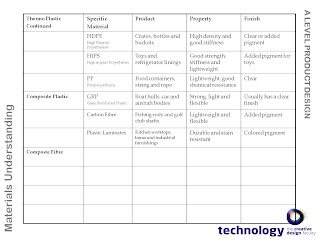

Plastics

Two main categories

Thermosetting plastics – Are heated and moulded into shapes and are very hard to mould back into their original shapes.

Thermoplastics – They will soften when they are heated, and can be shaped when hot.

Summary of plastics

. Good electrical and thermal insulators

. Good strength to weight ratio

. Generally good resistance to atmosphere and chemical erosion

. Low melting point = Less heat required therefore saving money

. Lightweight

. Available in a wide range of colours and transparency – Simply by adding a coloured pigment to the material

Plastic names – Thermo polymers

ABS – Acrylonitrile Butadiene Styrene

CA – Cellulose acetate

Nylon – Polyamide

PMMA – Polymethylmethacrylate – Acrylic

PP – Polypropylene

HIPS – High Impact polystyrene

PS – Polystyrene

LDPE – Low density polyethylene

HDPE – High Density polyethylene

Thermoset polymers

Epoxy resins – Surface coatings, encapsulation of electronic components and adhesives

Melamine – Tableware and decorative laminates

Polyester resins – Castings and used in GRP

Urea formaldehyde – Electrical fittings and adhesives

The Hooded sweater I never should of purchased.

When on holiday a hooded sweater caught my eye. At the time the well known ‘Super dry’ sweaters were very popular, so my mind was made up therfore I purchased it. Shortly after purchasing the sweater, I then realised that it was of low quality. At first glance, the sweater looked extremely trendy and extremely attractive with regards to the simple colour and the printed logo.

The sweater was apparently manufactured by the popular brand Super Dry which persuaded me to buy it. I had then realised that the sweater I had purchased was a fake and was of extremely low quality. I knew I had made a mistake when buying the sweater as it looked fabulous but was let down by the functionality of the sweater (to keep the buyer warm).

The functionality of the sweater was poor as the quality of the material was terrible and I could tell that the sweater was made very cheaply and made with no time or care.

Another flaw with the product was that when (after washing the sweater and it had dried) the texture of the cotton was extremely unsmooth unlike the surface beforehand.

As it was made by a very popular brand, I thought that the quality of the sweater would be amazing, but it goes to show that just because the product is visually appealing it doesn’t mean that the functionality of the product will be of equal quality.

Instead of buying the most ‘fashionable’ and best looking, I will choose quality over aesthetics.

Subscribe to:

Comments (Atom)